IGUnit Glass

Double glazing refers to the process of creating an Insulated Glass Unit (IGU), which involves two or more lites of glass separated by an air gap and hermetically sealed to form a single unit. This air gap significantly enhances the thermal performance of the glass, making double glazed windows and double glazed doors a popular choice in architectural applications. Typically, an IGU consists of two glass panels, but triple glazing can also be found in extremely cold climates. These units can be framed in a sash or frame and are manufactured in Sydney using advanced techniques.

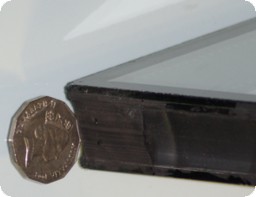

The air space between the glass layers provides the insulative properties, which can be enhanced by filling the gap with inert gases like argon or krypton. This makes uPVC double glazed windows and doors highly energy efficient. Desiccants are used to prevent condensation and improve insulation. Occasionally, air is removed to create a partial vacuum, drastically reducing heat transfer through convection and conduction. This method is known as evacuated glazing. The air gap typically ranges from 8mm to 22mm, with 16mm being the optimal thickness recommended for most applications.

Spacers are essential for maintaining the separation of the glass panes and housing the desiccant, which absorbs moisture. Silicone sealant is applied to the exterior for structural integrity, while butyl sealant serves as the primary defense for the hermetic seal. Utilizing insulated window and door products, such as energy efficient windows, significantly lowers energy costs, enhances comfort, reduces condensation, and diminishes the fading of interior furnishings.

During summer, double glazed windows and doors with a low solar heat gain coefficient decrease the amount of heat entering the home, improving comfort and reducing cooling energy requirements. In cooler seasons, these products create warmer interior glass surfaces, minimizing frost and condensation. Additionally, they protect against UV rays, which can cause fading and degradation of materials like carpets, curtains, and artwork.

Applying a film or coating to the glass surface can further enhance heat and sound insulation. This film can be made of polyester or metal, offering a reflective appearance and a one-way mirror effect, improving both insulation and safety in case of breakage. Secondary glazing, a cheaper alternative, involves adding a layer of glazing inside the existing window for extra insulation.

Key Performance Requirements:

-

Thermal Insulation: The primary function of IGUs is to reduce thermal heat transfer from the outside. The effectiveness depends on the dryness of the air inside the IGU and the quality of the hermetic seal. Dry air is a poor heat conductor, and the air gap significantly reduces heat conduction through the glass.

-

Structural Strength: IGUs are heavy and must maintain strength, especially in structural glazing applications. The type and quality of spacers, sealants, and spacer joints are crucial for maintaining this strength.

-

Fogging Protection: Properly manufactured IGUs provide better protection against fogging than single panes of glass. However, poor quality control can lead to fogging issues.

Key Quality Areas:

-

Desiccant Quality: Using the correct type and quantity of desiccant is crucial for absorbing moisture and maintaining air dryness within the IGU. Contact with ambient air during filling must be avoided.

-

Spacer Joints: Ideally, spacers should have no joints. Automatically bent spacers with a single side joint are preferred over multiple corner joints for better structural strength.

-

Controlled Environment: IGUs should be manufactured in a controlled environment to prevent moisture absorption and dust entry.

-

Sealant Quantity: The secondary sealant provides rigidity, and its quantity must be appropriate for the IGU size.

-

Equipment: Proper manufacturing equipment is essential for producing high-quality IGUs that perform well over their lifecycle.

Spacer Thickness: Our IGUs are available in various thicknesses (6, 8, 10, 12, 15, 18, 24mm) to meet local requirements and exceed customer expectations. All our energy efficient windows and doors are meticulously manufactured in Sydney.