Environmentally Friendly

At our manufacturing facility in Sydney, we are deeply committed to minimizing our environmental impact by employing sustainable practices. By investing in precision-quality machinery and advanced manufacturing software, we have significantly enhanced the efficiency of producing double glazed windows and double glazed doors. These investments have been crucial in reducing off-cuts and errors. Any remaining off-cuts, whether profile or reinforcement, are repurposed into samples for architects, builders, and tradespeople. Our goal is to achieve zero waste of profile and reinforcement materials every month. Additionally, any assembled windows and orders that were canceled are given to existing clients for free.

Our focus on environmentally sound practices is evident throughout our business operations in Sydney. We discourage the use of print media, opting instead to send all brochures, reports, quotes, and official correspondence electronically. For service repair calls on windows and doors made by our competitors, our staff aims to provide the most practical and cost-effective solutions, never recommending a full replacement unless absolutely necessary. Clients replacing their old uPVC double glazed windows can have them recycled at a minimal cost. Although the transportation and recycling costs are relatively high, we strive to offer our clients value for money and do not recycle products not manufactured by us for free.

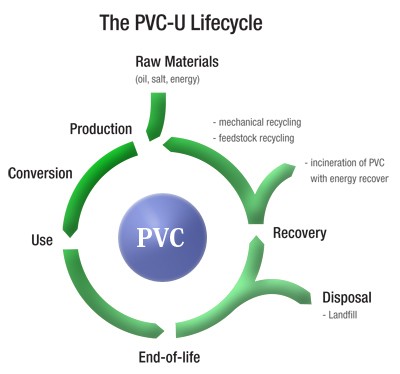

We aim to recycle as much as possible and use recycled products when feasible for transportation or installation. Currently, we only use virgin uPVC profiles in manufacturing windows and doors, but we are exploring the use of recycled composite materials as reinforcement alternatives. Even rubber and metal from old windows can be recycled into reusable, low-maintenance building products. Moreover, we choose suppliers with strong environmental credentials who comply with the latest legislation and continuously improve their practices.

Studies comparing the environmental impact of different window materials, including PVC, wood, and aluminum, have shown varying results. However, the most promising potential for reducing environmental impacts lies in optimizing the design and construction processes of energy-efficient windows. This means improving window quality to save heating energy during use and increasing the amount of secondary material used or reducing material required for the same function.

We offer our customers the opportunity to recycle their old uPVC window frames. They need only contact us, and we will either recut them into samples or send them to a vinyl recycling facility. Customers may also reconsider using popular aluminum windows due to the environmental damage associated with aluminum production. Studies have found that aluminum frames have the highest environmental burden due to pollutants released and high energy consumption during production.

PVC is a safe and versatile material, used for various applications, including bottles for mineral water, blood transfusion bags, and fine bore tubing for premature babies. It can be crystal clear or black as coal, rigid or flexible, and withstand extreme conditions, making it ideal for windows, water pipes, and electrical insulation.